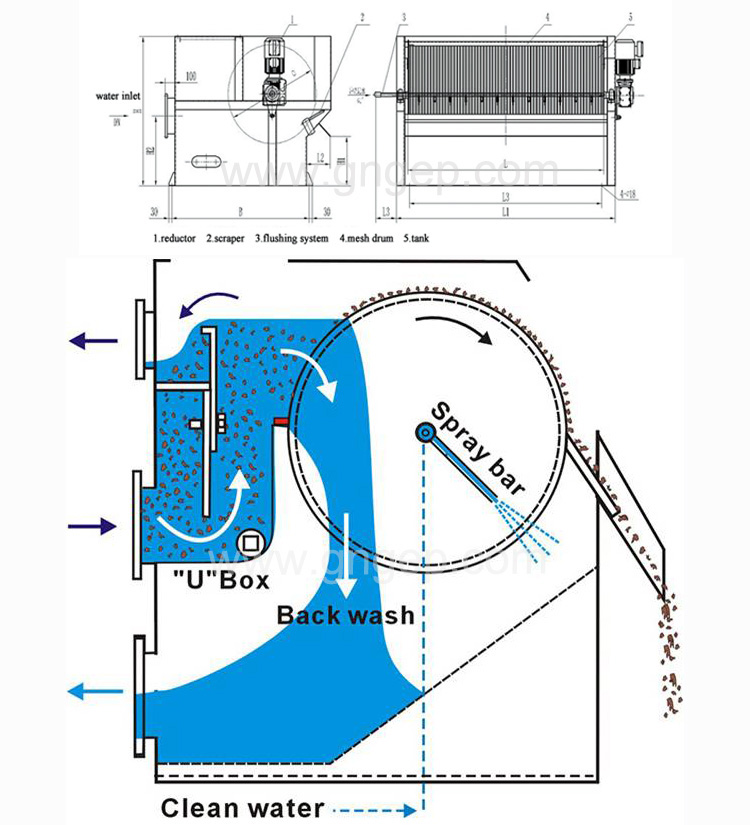

The product is used for solid/water separation which usually consists of more dense particles that need to be removed from the effluent. The effluent enters the inside of the rotating drum through the feed inlet and then passing over the distribution were on to the drum surface. The particles and water separate as the drum rotate with the solids staying on the screen and passing down the length of the drum helped by internal flights or a continuous scroll.

The solids will then discharge into a skip or other machinery for further treatment. The screened liquid travels through the drum before l leaving through the liquid outlet at the bottom of the machine. The RDS machine also contains an external pressurized water spraying system to help keep the drum clean and avoid clogging.

Working Principle

Features

The equipment is made of stainless steel, corrosion-resistant, compact structure, small footprint, easy to install, can be directly fixed with expansion bolts, the equipment can be used without grooves, and the inlet and outlet water are connected by pipes. The grid is trapezoidal in cross-section, making it difficult for the filter residue to clog the filter. Depending on the influent flow rate, the speed control motor is used to ensure that the work is kept in an optimal state. Special rinsing device can brush the impurities (even if it is rarely) on the surface of the grid. After two internal rinsings, the mesh cylinder can achieve the best cleaning effect. At the same time, the internal rinsing device is installed and will be attached. The dirt on the mesh is washed away.

Benefits

• With factory-direct service and spare parts.

• Removes excess feed, and other organic matter.

• Continuous filtering, even during backwashing.

• Very low operating cost and minimal backwash water consumption.

• Superior screen design for long service life.

• Ideal for sand filter backwash recovery.

Categories

Packaging & Shipping